Linyi Xiangying Wood Based Panel Machinery

Particle board Cage forming machine/Diamond forming machine

Particle board Cage forming machine/Diamond forming machine

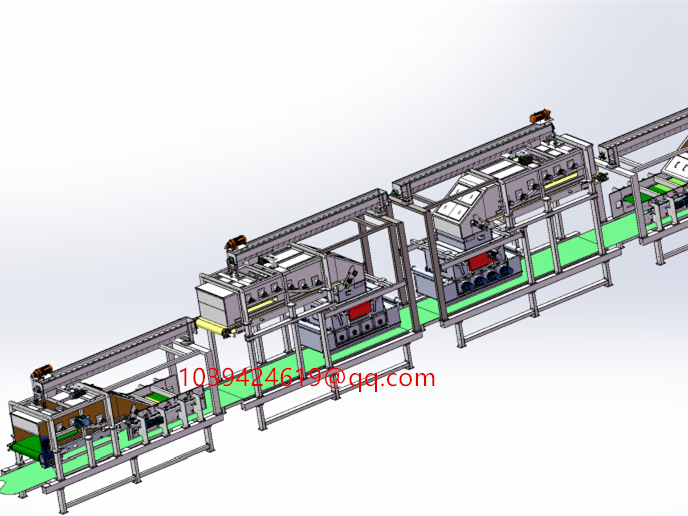

The forming machine is made up of three layers: upper, middle and lower. The whole machine includes a dozen parts including top conveying, dividing device, measuring box, measuring rake, measuring belt, paving and so on. The operation of the whole machine is controlled by electric interlock, and the main action can be automatically controlled according to the predetermined process requirements

The forming head is located in the lowest layer of the forming machine,its one of the most important equipment in the forming machine. which is composed of several groups of parallel diamond rollers, the roller surface with different thickness patterns, a total of 42 diamond rollers arranged in two rows, respectively driven by two decelerating motors, the chain drive between the diamond rollers, the rectangular bearing seat at both ends of the roller is installed in the chute on both sides of the plate. The gap between the rhomboid rollers is adjusted by adjusting mechanism between the adjacent bearing seats and pressed by bolts (plus spring pad). Fine roll gap 0.3-0.5mm adjustable, the specific size according to the actual production requirements, the pavement head is fixed on the pavement machine frame, and is provided with horizontal adjustment bolts. The diamond roller speed is adjustable between 80-120RPM and can be set according to the actual production requirements.

When the laying machine is working, the diamond roller group rotates in the same direction, the shavings scattered by the metering roller fall on the diamond roller group and move forward jumping, in which the fine shavings fall in the smaller gap at the beginning of the bin, the coarse shavings fall from the gradually larger gap behind, and some unqualified large shavings, micelles and large objects fall into the end of the waste spiral discharged to the machine. The lower rhomboid roller group of the coarse material section rotates in the opposite direction to the upper one, in order to achieve a three-layer gradation mechanism of particleboard slab.

Located in Linyi City,Shandong Province,"the Largest Wood BasedPanel Production Base of Asia”,LINYI XIANGYING MACHINERY MANUFACTURING CO.LTD (Linyi Xiangying Machinery Manufacturing Co.,Ltd)is an aggressive manufacturer which specialized in research, development, manufacture and marketing in the field of wood working machines.Since it was established in 1992, Xiangying machinery keeping innovations and perfection to commit themselves in producing best quality machinery.Our main products are Particle board production line,Plywood production line,MDF production line,Melamine laminating product online, etc. Based on our good quality as well as perfect service ,our business scope expands extensively both at home and in more than 20counties such as Vietnam, Malaysia, Pakstan, Bangladesh,Russia,Turkey and so on.And they are all well praised by our clients.Choose Xiangying machinery,Create measureless value.