Linyi Xiangying Wood Based Panel Machinery

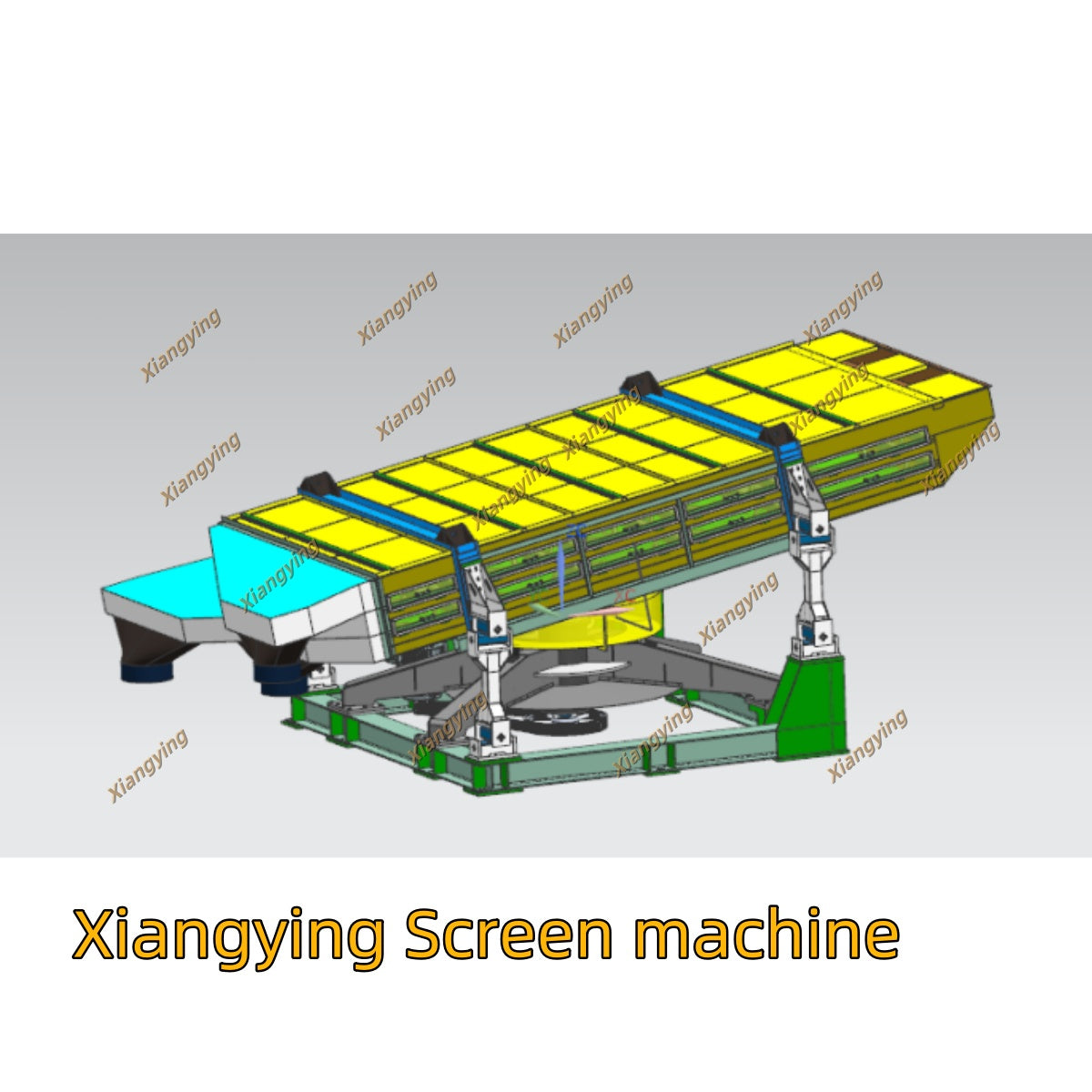

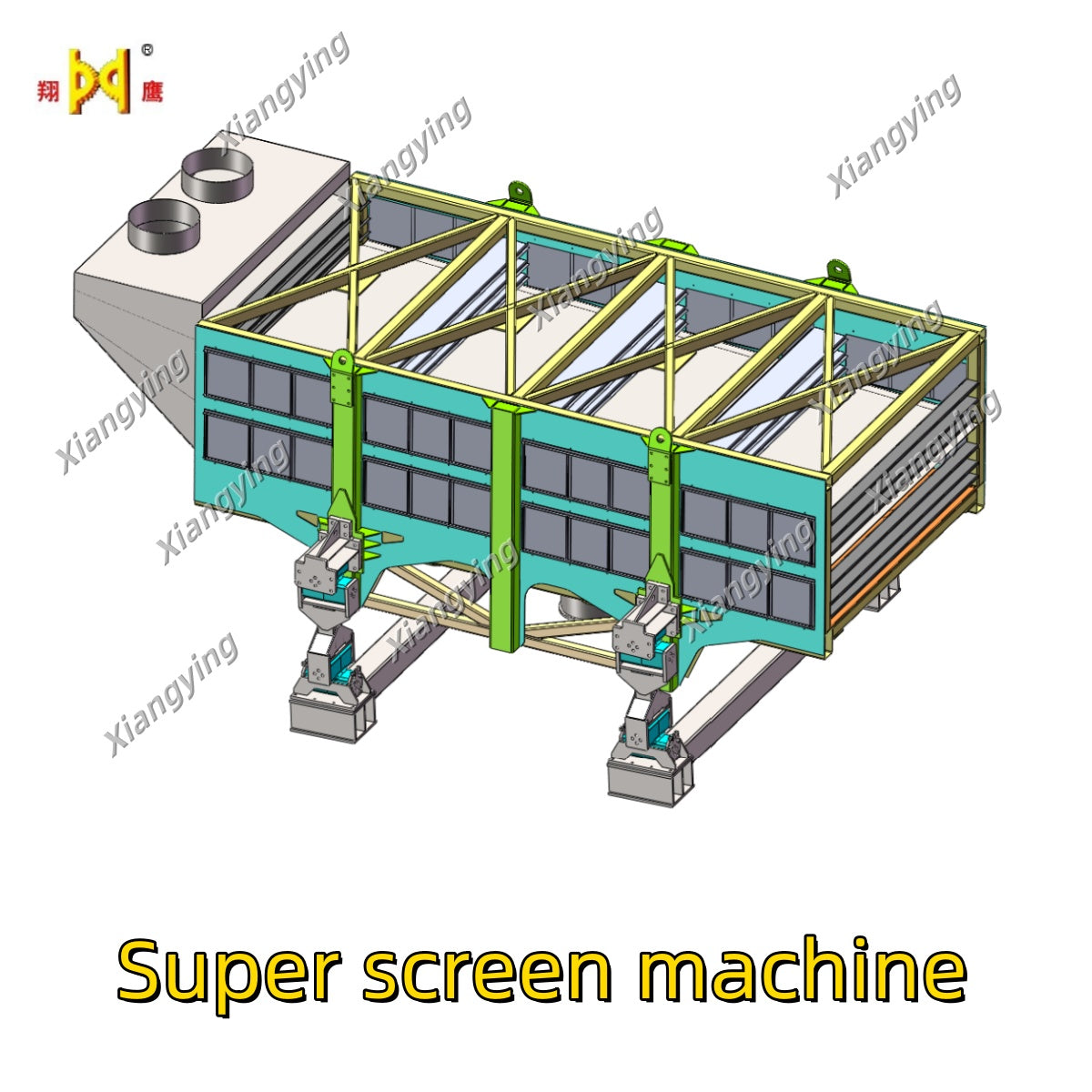

Particle board Swing screen machine/Sifter machine

Particle board Swing screen machine/Sifter machine

Swing screen is a specialized equipment for classifying wood chips in wood chip plants, paper mills and wood-based panel factories. It is usually used together with the chipping machine to sort out required chip sizes through removing sands, debris and oversized wood blocks. Screening sizes can be controlled by using specific screen nets of different hole sizes.

wing screen is composed of machine base, main body, vibrator, transmission device, universal joint pull-rod device,etc.

Main features

-Screening area optional from 8 to 20㎡and production capacity 100m3/ h-500m3/h;

-Compact structure and easy operations;

-High productivity and high qualification rate;

-Stable running and low power consumption;

-Reliable quality and easy operations and maintenance

The purpose of the rectangular screen is to screen and grade the material according to its geometric shape. The materials that can be screened are very wide, and can be used in the wood industry to screen wood chips, mixed shavings, sawdust, flax stalk, bagasse and other materials; It can also be used in food, feed, chemical industry, medicinal materials and other industries.

The working principle of the screen is driven by a motor through a triangular belt, driving the spindle rotation, the top of the spindle is equipped with an eccentric shaft (eccentric shaft can be adjusted from 0 to 35mm), the rectangular screen box is installed on the eccentric shaft, and the horizontal plane into 5-6 degrees of inclination, are supported on four plastic spring support rods. When the main shaft is rotating, the screen box is swinging, the screen box has a layer, two or three layers of screen mesh, screening materials from the feed box into the screen box, with the swing movement of the inclined screen box, the material on the screen box network both vertical jump, and along the inclined plane of the screen from the feed box to the discharge box to do spiral movement, the sifted material from the discharge box different outlet unloading. The lower end of the discharge port is provided with a flexible sleeve, which can be connected with the conveying device.

Located in Linyi City,Shandong Province,"the Largest Wood BasedPanel Production Base of Asia”,LINYI XIANGYING MACHINERY MANUFACTURING CO.LTD (Linyi Xiangying Machinery Manufacturing Co.,Ltd)is an aggressive manufacturer which specialized in research, development, manufacture and marketing in the field of wood working machines.Since it was established in 1992, Xiangying machinery keeping innovations and perfection to commit themselves in producing best quality machinery.Our main products are Particle board production line,Plywood production line,MDF production line,Melamine laminating product online, etc. Based on our good quality as well as perfect service ,our business scope expands extensively both at home and in more than 20counties such as Vietnam, Malaysia, Pakstan, Bangladesh,Russia,Turkey and so on.And they are all well praised by our clients.Choose Xiangying machinery,Create measureless value.